Calibration Setting

These are common settings applicable for all calibration sequences defined under the station/site/group. These settings define data to decide whether a calibration is successful or not as explained below

To add/modify calibration settings:

1. Click on Calibration then click on Calibration Setting

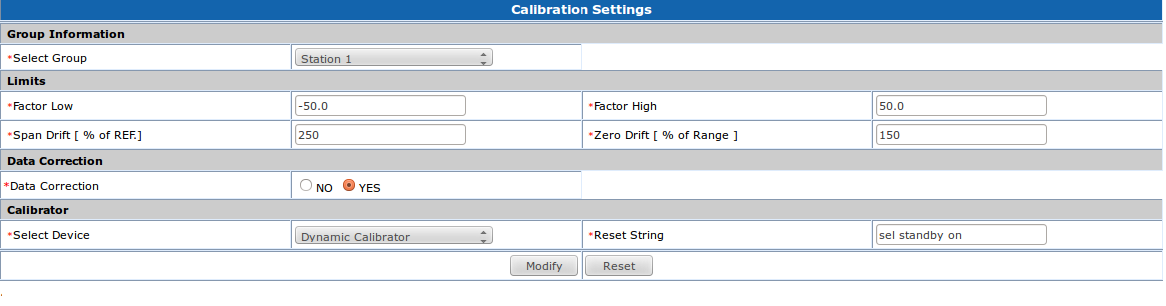

2. Calibration Settings page appears on the right hand side of the screen as shown below:

3. Select the group from 'Select Group' drop down box.

Limits – Set factor low and high limit range [typical 0.8 to 1.2]

- Span Drift [% of REF.] - Set the allowable percent Span variation (drift) [typical 4%-10%]. Drift = Measured span – Expected span.

- Zero Drift [% of Range] - Set the allowable percent Zero variation (drift) [typical 4%-10% of Range]. Drift = Measured zero – Expected zero.

- Data Correction – Yes/No this flag indicates if data correction is to be done after successful calibration. If yes, each data value read after calibration is corrected using the formula –

Y = Factor * X – Zero

Where, factor and zero as calculated on calibration mapping screen

X – read value of analyzer

- Calibrator section contains selection of calibrator device and reset string. Here it assigns calibrator device for the selected group. Reset string is used to reset the calibrator.

5. Click Save/Modify.

Validation rules for calibration:

For valid calibration following rules should be satisfied –

- Calculated Factor should be within the defined limits.

- Zero Drift or field ‘Zero’ should be within the defined variation

E.g. If zero drift is = 5% and range/reference = 500, so zero drift allowable range should be -25 to 25. This means calculated field ‘Zero’ should be between -25 and 25

- Span Drift should be within the defined variation. This is Measured Span – Expected Span

E.g. If span drift = 4% and range/reference = 500, so span drift allowable range should be -20 to 20.

If any of the above rules are not satisfied, then the calibration is not valid.

Error handling:

- If any error occurred during calibration, then abort the calibration and reset calibrator. Store the status.

- Don't allow to change the cal. sequence during calibration in progress.

- If calibration in progress for one analyzer, don't allow to start calibration for any other analyzer on same site.